LESS Mechanism

LESS is an innovative mechanism that converts circular to reciprocating motion (and vice versa), and it is therefore a replacement for the traditional crankshaft-pushrod configuration.

This results in 50% smaller size and cost mechanism, for same power, 3-5% improved efficiency, fuel consumption and emissions.

- LESS size

- LESS components

- LESS fuel consumption

- LESS emissions

- LESS vibrations

LESS is applicable in all Internal Combustion Engines from lightweight aircrafts to maritime and power tools, as well as broader hydraulic and pneumatic motors.

LESS can also work conversely and turn rotary movement to reciprocal, which is the main operating principle of several types of Pumps & Compressors.

How LESS works

Principle of Operation

The mechanism comprises of two symmetric annular undulated stators (red items in the next figure) and an annular undulated rotor (white item). The upper and lower undulated surfaces of the rotor are symmetric to those of the stators respectively.

The rotor slides on both stators simultaneously, with every point of the rotor conducting a smooth undulated move.

Usage in an ICE

The rotor can be appropriately connected to a piston and an axel. Any mechanical force on the piston (e.g., resulting from combustion as shown in the animation) is transmitted through the rotor to the axel as torque and vice versa.

Since it uses the same thermodynamic cycles as the traditional engines, the LESS mechanism is applicable to all kinds of ICEs (Diesel, Gasoline, LPGs etc).

Advantages

Size

Compared to a traditional engine, it has 50% less volume , due to:

- completion of an operational cycle in one rotation instead of two in conventional 4-stroke ICEs

- elimination of connecting rod

- elimination of balancing material through proper cylinder arrangement

This results in a smaller, lighter, and cheaper engine, for the same amount of power.

Performance

Thanks to the sinusoidal and fully symmetrical design of the undulated surfaces, the piston moves in a smooth reciprocal, fully harmonic way.

The LESS mechanism has fewer moving parts (only 1), therefore it has less mechanical wear and tear, and maintenance costs. And thanks to the hydrodynamic lubrication of the rotor, it has minimal friction and wear.

It has no side forces on the piston, resulting in less friction between the cylinder and the piston.

Moreover, LESS can introduce a delay in the Top and Bottom Dead Centers of the piston (via the undulated surfaces’ design), a shortcoming of the crankshaft mechanism resulting in high energy losses and low efficiency rate due to imperfect combustion. With LESS, the combustion time can be delayed as necessary, resulting in increased performance and efficiency.

The delay in the Top Dead Center enables a near-perfect combustion and results in higher temperature and pressure in the combustion chamber, and therefore significantly less emissions, and 3-5% improved fuel consumption and efficiency ratio.

2-Stroke

Finally, LESS can be replace a 2-stroke ICE. 2-stroke ICEs are already famous for their weight & cost advantages compared to a 4-stroke, however, they are highly polluting, as they consume and burn oil.

With LESS, a 2-stroke ICE can be replaced with a 4-stroke of the same size, without the need to burn oil.

Furthermore, LESS can be used as a 2-stroke ICE at 25% of the size/cost of comparative 4-stroke conventional ICE. This is achieved through a 4-stroke LESS ICE with fuel injection that operates as a 2-stroke ICE.

In this configuration, taking advantage of the delay in the Top and Bottom Dead Centers, we can extract the exhaust fumes and introduce air through the use of a Turbocharger. Therefore, LESS eliminates the need for oil in the fuel mix and the 2-stroke LESS operates with antipollution technology.

Patent Application

Behind the LESS operation and benefits lie a set of mathematical properties. We have filed patent applications in Hellenic IPO, WIPO and USPTO and have received positive IP search reports from 3 different sources in 2018.

Current Status

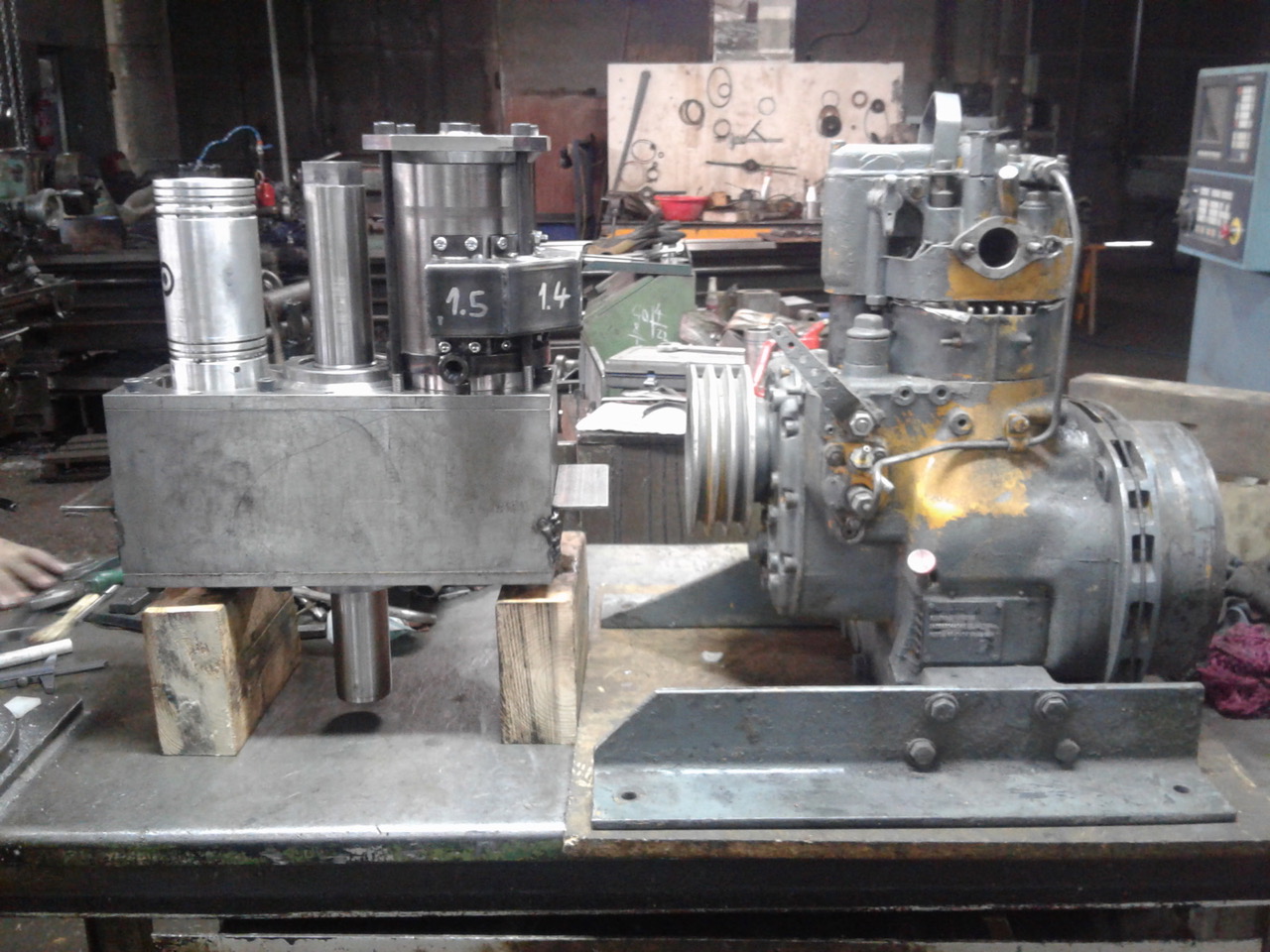

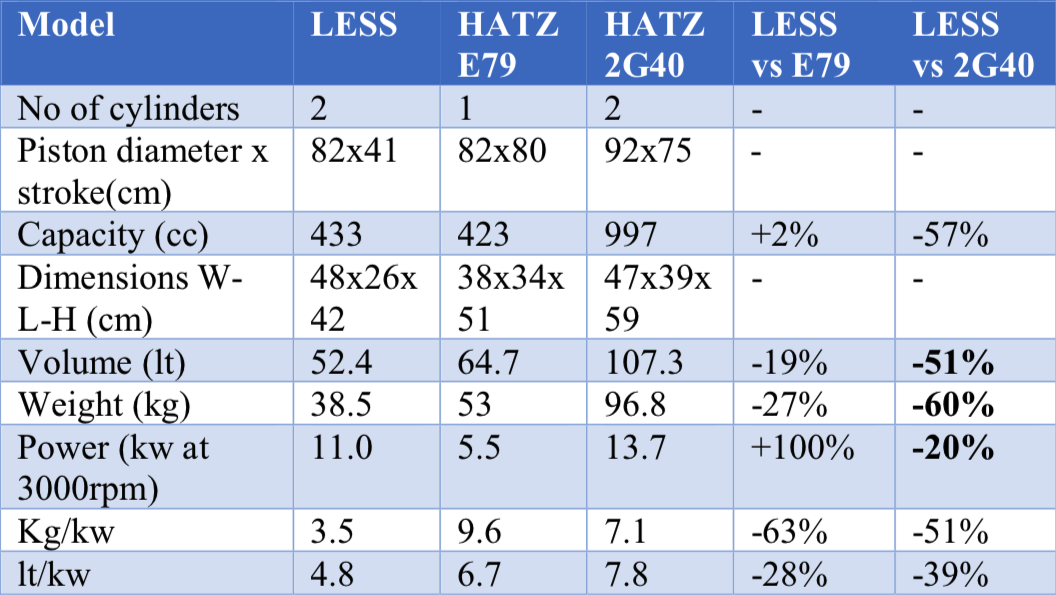

We are at TRL6 stage with working prototypes both as a compressor and as a 2-cylinder, 4-stroke, petrol powered ICE. Our prototype already proves LESS’ size benefit with 50% less volume and 60% less weight vs conventional engine of roughly comparable power output.

More specifically, our prototype is a 2-cylinder - (2x216cc, 4-stroke) and was built to be the same size as a general-purpose HATZ E79 engine we had available (1-cylinder, 1x423cc, 4-stroke). Even though it’s roughly the same size, it has roughly twice the power (11kW vs 5.5kW @3000rpm).

These are the two engines:

And a comparison table of the LESS Engine Prototype with various general purpose engines:

Below, you can find a video of the engine prototype in use:

And last but not least, here you can watch a 3D design of the LESS Mechanism principle and our first Engine Prototype.

Market Applications

With its unique advantages, a LESS engine has extreme potential in many areas such as:

- Hybrid cards, where the size of the ICE is important, and the cost the ICE can be significantly reduced.

- Motorbikes & Marine applications, where it can replace 2-stroke engines with a 4-stroke of the same size without polluting & burning oil.

- Handheld power tools such as chainsaws, lawn mowers etc, reducing both the cost and weight.

- Light and ultralight aircrafts, where reciprocating ICEs are in use, significantly reducing the weight of the aircraft.

We are actively looking for collaborators and licensing partners. If you are interested, please contact us at the email address below.